The quality and performance of drawer slides are essential to the functionality and longevity of furniture. To ensure that these components meet industry standards, a Drawer Slides Manufacturer must implement rigorous quality control practices throughout the production process. These practices not only ensure smooth operation but also guarantee that the slides are durable, safe, and reliable over time.

Leading manufacturers like Drawer Slides Manufacturer adhere to strict quality control measures to ensure their products deliver consistent performance. This attention to detail is vital for producing high-quality drawer slides that can withstand the demands of both residential and commercial furniture.

Material Inspection and Selection

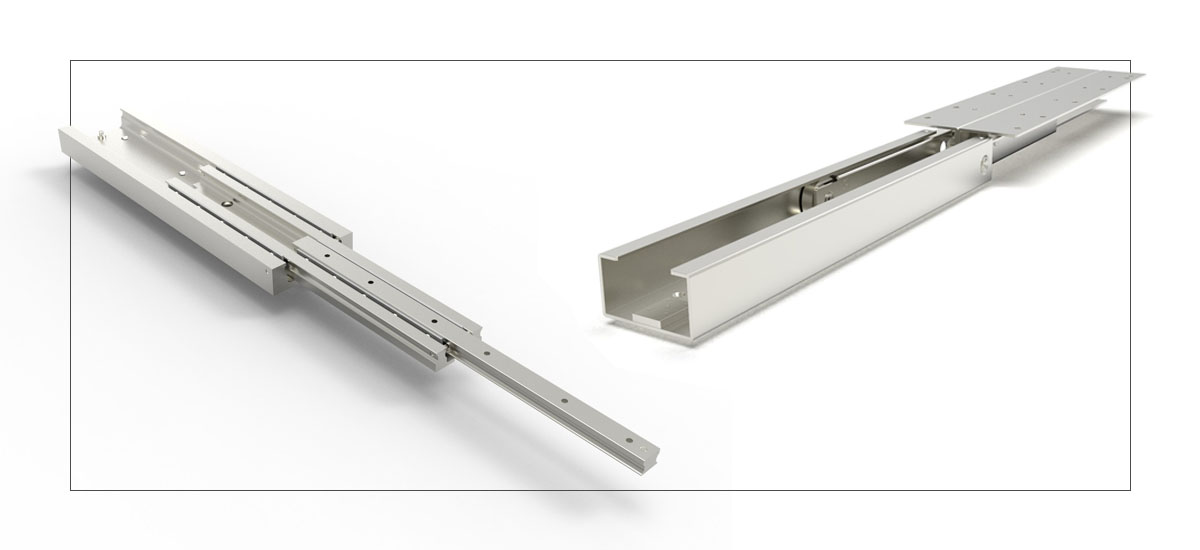

One of the most critical aspects of quality control in drawer slide manufacturing is material selection. A Drawer Slides Manufacturer starts by sourcing high-quality raw materials such as steel, aluminum, or other alloys that offer strength, durability, and resistance to wear. Each material is thoroughly inspected to meet specific standards, including tensile strength, corrosion resistance, and surface finish.

Before the manufacturing process begins, incoming materials undergo a detailed inspection to verify their properties. This ensures that only materials with the necessary performance characteristics are used, which directly impacts the overall durability and function of the final product.

Dimensional Accuracy and Tolerance Checks

Precision is crucial in drawer slide manufacturing. Even the slightest deviation in the dimensions of the components can lead to improper alignment, friction, or poor performance. To maintain high standards, manufacturers use advanced measuring tools and systems to check the dimensions of each part during production.

Quality control teams perform regular tolerance checks at various stages of the manufacturing process. These checks help ensure that each part of the drawer slide fits together perfectly, allowing for smooth and effortless operation. Tolerances are carefully controlled, with deviations within the allowable range to prevent any functional issues.

Functional Testing and Durability Evaluation

Once the drawer slides are assembled, they undergo rigorous functional testing to ensure they meet performance standards. These tests simulate real-world usage, including extended cycles of opening and closing, to evaluate the smoothness of operation and to check for wear and tear.

Durability is another key aspect of quality control. Drawer Slides Manufacturers conduct stress tests to ensure that the slides can withstand various loads and conditions. They test the slides’ ability to support different weights, open and close under heavy use, and function reliably over time. Additionally, many manufacturers subject their products to environmental testing to assess their resistance to temperature fluctuations, humidity, and other factors that could affect performance.

Load-Bearing Capacity Tests

Drawer slides are expected to handle different load capacities depending on their application. A Drawer Slides Manufacturer ensures that their slides meet the specific weight requirements for each intended use. To verify this, they conduct load-bearing tests in which slides are subjected to varying levels of weight and force.

These tests are crucial for ensuring that the drawer slides can handle heavy-duty applications, such as toolboxes, kitchen cabinets, and commercial furniture. The tests simulate everyday usage to assess whether the slides remain functional under pressure or if they show signs of failure, such as bending, breaking, or misalignment.

Surface Treatment and Corrosion Resistance

The longevity of drawer slides also depends on their resistance to wear and corrosion. To enhance durability, manufacturers apply various surface treatments, including galvanizing, anodizing, or coating the slides with protective finishes. These processes increase the resistance of the slides to rust, corrosion, and friction, ensuring smooth operation even in challenging environments.

As part of the quality control process, manufacturers regularly test the effectiveness of these treatments by subjecting the slides to corrosion tests, including salt spray and humidity tests. These tests simulate harsh environments to evaluate how well the surface treatment protects the slides from damage over time.

Functional Features and Custom Testing

In addition to basic performance testing, many modern drawer slides come with additional features, such as soft-close or self-close mechanisms. These features are tested for functionality to ensure they operate as designed. The manufacturer evaluates the smoothness and precision of the soft-close function to confirm that the drawer closes gently without slamming.

For customized solutions, quality control teams also carry out tests specific to the customer’s requirements. Whether it’s a unique load-bearing specification or a custom finish, the slides are tested for both functionality and aesthetics to ensure they meet the desired standards.

Continuous Monitoring and Improvement

Quality control is an ongoing process for Drawer Slides Manufacturers. To maintain high standards, manufacturers continuously monitor their production processes and implement improvements based on feedback from testing and customer input. Regular audits, inspections, and quality reviews ensure that production remains in line with industry standards and customer expectations.

Furthermore, manufacturers often invest in advanced technologies, such as automated inspection systems, to improve the accuracy and efficiency of their quality control procedures. These systems help detect potential defects early in the production process, allowing for quick corrections and minimizing waste.

Conclusion

Quality control is at the heart of drawer slide manufacturing, ensuring that each component meets rigorous standards for performance, durability, and safety. By selecting the right materials, conducting detailed testing, and implementing strict tolerance checks, Drawer Slides Manufacturers can produce high-quality slides that will perform reliably over time. The attention to detail throughout the manufacturing process guarantees that the finished product enhances the longevity of furniture, offering smooth operation, stability, and durability for residential, commercial, and industrial applications.