The efficiency of manufacturing lead times plays a critical role in the global sunglasses industry. Lead time, which refers to the period from placing an order to receiving the finished product, directly affects supply chain management, inventory planning, and market responsiveness. China, as a dominant hub for sunglasses production, has developed sophisticated systems and processes that optimize lead times while maintaining high-quality standards. Understanding these timelines and the factors that influence them is essential for international brands and distributors who rely on China for their eyewear sourcing.

China Sunglasses Manufacturers have invested heavily in technology, production infrastructure, and supply chain coordination to reduce lead times without compromising quality. Efficient lead times allow manufacturers to meet seasonal demands, respond quickly to fashion trends, and fulfill large-scale orders for global markets. The following sections explore the key factors that influence lead times in Chinese sunglasses production, including production scale, material availability, manufacturing processes, and logistics.

Production Scale and Capacity

The scale of production is a significant determinant of lead times. China’s sunglasses factories range from small workshops to massive industrial complexes capable of producing millions of units annually. Large-scale manufacturers often operate multiple production lines dedicated to different models or components, allowing simultaneous production and faster overall throughput.

High production capacity enables factories to manage multiple orders concurrently and adapt to urgent requests. This is particularly advantageous for international clients with tight seasonal deadlines, such as summer collections or fashion campaigns. By efficiently utilizing production lines and labor, manufacturers can reduce the waiting period between order placement and delivery.

Raw Material Procurement and Inventory Management

Lead times are closely tied to the availability of raw materials. Sunglasses production relies on high-quality plastics, metals, lens materials, coatings, and accessories like hinges and screws. China-based manufacturers maintain strong relationships with local and international suppliers to ensure consistent access to these materials.

Effective inventory management systems are crucial in reducing delays. Many manufacturers keep essential components in stock, including popular frame colors, lens types, and hardware. By maintaining buffer inventories, factories can initiate production immediately upon receiving an order, minimizing lead time caused by sourcing delays. Strategic procurement planning also helps factories respond quickly to fluctuations in raw material costs or supply disruptions.

Design, Prototyping, and Customization

The design and prototyping phase can significantly influence lead times, especially for customized or private-label sunglasses. Chinese manufacturers utilize advanced Computer-Aided Design (CAD) software and 3D printing technologies to accelerate product development. These tools enable rapid prototyping, allowing clients to review and approve designs quickly before mass production begins.

Customization, such as adding logos, selecting lens tints, or applying specialized coatings, can extend lead times if not managed efficiently. Experienced China sunglasses manufacturers integrate modular production systems that allow customization without interrupting overall production flow, ensuring that bespoke requirements do not cause significant delays.

Manufacturing Processes and Technology Integration

Modern production technologies play a critical role in reducing manufacturing lead times. Injection molding for plastic frames, CNC machining for metal components, automated lens cutting, and robotic assembly lines all contribute to faster, more precise production. Automation reduces the likelihood of errors, minimizes rework, and allows multiple components to be processed simultaneously.

In addition, process optimization techniques such as lean manufacturing and workflow standardization help streamline operations. Factories track production metrics in real-time, identify bottlenecks, and adjust labor allocation or machinery settings to maintain consistent output. By combining automation with efficient production planning, manufacturers can achieve faster turnaround times without compromising quality.

Quality Control and Inspection

While rapid production is important, quality cannot be overlooked. Lead times also account for in-process inspections and final product evaluations. China sunglasses manufacturers implement systematic quality control measures at each stage of production, including frame inspections, lens clarity testing, UV protection verification, and functional checks for hinges and screws.

Efficient factories integrate quality control into the production flow rather than treating it as a separate stage. This approach reduces the time spent on rework and ensures that defective products are identified early. By combining proactive quality control with automated inspection systems, manufacturers maintain product standards while keeping lead times short.

Logistics and Export Considerations

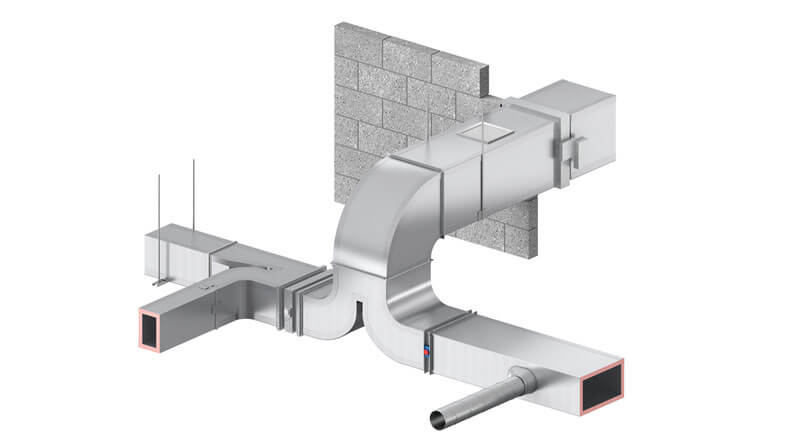

Once production is complete, logistics and shipping play a crucial role in the overall lead time. China’s advanced transportation infrastructure, including ports, rail networks, and air cargo services, facilitates efficient export to global markets. Manufacturers often work closely with freight forwarders to consolidate shipments, select optimal routes, and manage customs documentation to prevent delays.

Lead times can also vary based on the destination market, customs clearance requirements, and shipping method chosen. Expedited air shipments reduce delivery times but may increase costs, while sea freight is more cost-effective but requires longer transit periods. Experienced manufacturers provide guidance on balancing cost, speed, and reliability to meet client expectations.

Seasonal and Market Influences

Lead times in sunglasses manufacturing are also influenced by market seasonality. Demand peaks during spring and summer months, as well as during major fashion release cycles. Factories often experience higher order volumes during these periods, which can extend lead times if production lines are operating at full capacity. Advanced planning and early order placement are essential strategies for international buyers to ensure timely delivery during peak seasons.

Conclusion

Manufacturing lead times in China sunglasses production are shaped by multiple factors, including production scale, material availability, technological integration, quality control, and logistics. China sunglasses manufacturers leverage their experience, advanced machinery, and efficient supply chains to minimize delays while maintaining high-quality standards. By understanding these factors, international brands can better plan their orders, manage inventory, and respond to market demands effectively. Efficient lead times, combined with consistent quality, are key reasons why China remains a preferred hub for global sunglasses production.