Industrial Density Meter: Essential Tool for Process Optimization

In industries where precision is critical, an industrial density meter plays a vital role in optimizing processes and ensuring consistent product quality. By providing accurate, real-time measurements of fluid and slurry density, these devices help businesses improve efficiency, reduce costs, and maintain high standards of production. This article explains how industrial density meters work, their benefits, and their wide-ranging applications across industries.

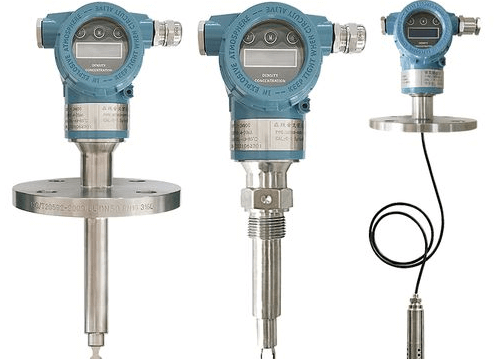

What Is an Industrial Density Meter?

An industrial density meter is a device used to measure the density of liquids, slurries, or gases in real-time. Unlike manual sampling and offline testing, these meters offer continuous data directly from the process, helping operators make immediate decisions to enhance performance and quality.

How Does It Work?

Industrial density meters use various technologies to determine density:

- Vibrating Tube Technology: Measures the natural frequency of a vibrating U-shaped tube filled with the process fluid. The vibration changes based on the fluid’s density.

- Ultrasonic Technology: Sends ultrasonic waves through the fluid and measures the speed of sound, which correlates with its density.

- Coriolis Flow Meters: Simultaneously measure mass flow rate and density using Coriolis force principles.

Benefits of Using an Industrial Density Meter

1. Real-Time Process Control

With continuous monitoring, operators can quickly detect and correct deviations, reducing the risk of defective products.

2. Enhanced Product Quality

Precise density measurements ensure that product specifications are consistently met, improving quality and customer satisfaction.

3. Cost Efficiency

Accurate density control reduces waste, optimizes resource usage, and lowers operational costs.

4. Non-Invasive Measurement

Industrial density meters can be installed directly in the pipeline or vessel, providing non-intrusive measurements without disrupting the process.

5. Wide Range of Applications

These meters are suitable for a variety of industries, from oil and gas to food processing and pharmaceuticals.

Key Features to Consider

1. Accuracy and Precision

Look for a meter that offers high accuracy, especially if your process demands tight tolerances.

2. Operating Range

Ensure the meter can withstand the temperature, pressure, and chemical conditions of your process.

3. Connectivity and Integration

Modern industrial density meters come with digital communication protocols such as Modbus, HART, or Ethernet for easy integration into control systems.

4. Maintenance and Durability

Select a device that is easy to maintain and built to handle harsh industrial environments.

5. Multi-Parameter Measurement

Some meters can measure additional parameters like temperature, flow rate, or concentration, providing more comprehensive data.

Applications of Industrial Density Meters

1. Oil and Gas Industry

- Monitor crude oil density for refining and transportation.

- Optimize drilling fluid density to improve well stability.

2. Food and Beverage Industry

- Control the density of syrups, sauces, and dairy products.

- Ensure consistency in beverage production.

3. Chemical and Petrochemical Industry

- Maintain precise density control in chemical reactions.

- Monitor polymer concentrations in manufacturing processes.

4. Mining and Mineral Processing

- Measure slurry density in ore extraction and processing.

- Improve tailings management for environmental compliance.

5. Pulp and Paper Industry

- Optimize the density of pulp slurries for consistent paper quality.

Why Industrial Density Meters Are Essential for Process Optimization

By integrating an industrial density meter into your operations, you can:

- Improve operational efficiency by reducing downtime and waste.

- Ensure product consistency to meet regulatory and quality standards.

- Make data-driven decisions with accurate, real-time measurements.

- Maximize profits by optimizing resource usage and minimizing production errors.

Conclusion

An industrial density meter is a must-have tool for process optimization in various industries. Whether you’re in oil and gas, food production, or chemical manufacturing, these devices offer the accuracy, efficiency, and reliability needed to stay competitive. Investing in the right meter can lead to significant long-term benefits, including enhanced quality control, cost savings, and improved overall performance.