Ensuring the durability and longevity of buildings requires attention to both construction materials and protective measures. Gaps, cracks, and voids in structural components can compromise stability, reduce insulation efficiency, and allow moisture and pests to infiltrate. One of the most effective solutions for enhancing structural durability is PU foam sealant, which provides insulation, adhesion, and additional support to various building elements.

Understanding PU Foam Sealant

PU foam sealant is a polyurethane-based material that expands upon application to fill gaps, cracks, and cavities. Its unique composition allows it to bond with a variety of surfaces, including wood, metal, brick, and concrete. For those seeking reliable solutions, PU foam sealant comes in specialized formulations designed to optimize both sealing and structural reinforcement. This dual function makes it an ideal choice for improving building durability while also enhancing energy efficiency.

How PU Foam Sealant Contributes to Structural Integrity

1. Filling Gaps and Voids

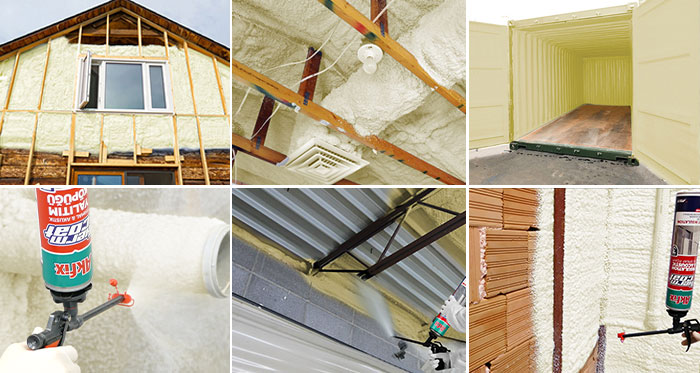

One of the primary ways PU foam sealant enhances structural durability is by filling gaps and voids within walls, around windows and doors, and between construction materials. These gaps can weaken the overall structure by allowing movement, drafts, or water intrusion. When the foam expands and cures, it forms a rigid, cohesive mass that stabilizes these areas and reduces the risk of material shifting over time.

2. Supporting Framing and Fixtures

PU foam sealant provides additional support to frames and fixtures. For instance, when used around window and door frames, it helps hold them securely in place, reducing wobbling or movement that could lead to damage. Similarly, in wall cavities or between panels, cured foam acts as a filler that distributes stress evenly, preventing localized weaknesses and enhancing overall stability.

3. Moisture and Pest Protection

Moisture infiltration is a major cause of structural degradation, leading to wood rot, metal corrosion, and mold growth. PU foam sealant’s closed-cell structure prevents water from penetrating gaps and cavities, keeping critical structural components dry. Additionally, the foam acts as a barrier against insects and pests that might otherwise damage materials over time. This protection contributes directly to the long-term durability of a building.

Thermal and Acoustic Benefits

Beyond structural support, PU foam sealant also improves thermal and acoustic performance. By filling gaps and forming airtight seals, it prevents heat loss and reduces energy consumption. Its density and adhesion also help dampen sound transmission between rooms or from external sources. These properties not only enhance occupant comfort but also reduce stress on HVAC systems, indirectly supporting the structural lifespan of the building.

Application Techniques for Maximum Durability

1. Surface Preparation

Proper surface preparation ensures that PU foam adheres effectively and provides optimal support. Surfaces should be clean, dry, and free of dust, grease, or loose materials. Any contaminants can reduce adhesion and compromise the foam’s ability to reinforce the structure.

2. Controlled Application

Using a foam gun or nozzle allows precise control over the amount and placement of PU foam sealant. Apply the foam gradually, especially in large cavities, to ensure even expansion and prevent overfilling. Layering foam for deep gaps ensures consistent structural reinforcement.

3. Curing and Trimming

Allow the foam to fully cure before trimming excess material. Proper curing ensures the foam achieves maximum rigidity and adhesion, providing long-lasting support. Trimming ensures a neat finish and allows for subsequent construction or finishing work without compromising the structural benefits.

Common Structural Applications

- Window and Door Frames: Securing frames and preventing movement that could weaken walls.

- Wall and Roof Cavities: Filling voids to stabilize panels and reduce stress points.

- Pipe and Duct Penetrations: Supporting surrounding materials and preventing air and moisture infiltration.

- Floor Gaps and Joists: Reinforcing weak areas and improving load distribution.

PU foam sealant’s versatility makes it an effective solution for a wide range of structural reinforcement needs.

Conclusion

PU foam sealant enhances structural durability by filling gaps, supporting frames and fixtures, and protecting against moisture and pests. Its insulating and sound-dampening properties further contribute to a building’s longevity and energy efficiency. By applying PU foam sealant correctly, including surface preparation, controlled dispensing, and proper curing, homeowners and contractors can significantly improve the stability, performance, and lifespan of their structures. Incorporating PU foam sealant into construction and maintenance projects ensures stronger, more resilient buildings capable of withstanding the challenges of daily use and environmental exposure.