Ductwork is a critical component of any HVAC system, responsible for transporting conditioned air efficiently throughout a building. Over the years, HVAC technology has evolved, offering different duct options to meet the demands of energy efficiency, installation convenience, and system performance. Two primary types of duct systems are commonly used: traditional ductwork with on-site insulation and pre-insulated ductwork. Understanding the differences between these systems can help contractors, engineers, and facility managers make informed decisions for residential, commercial, and industrial projects.

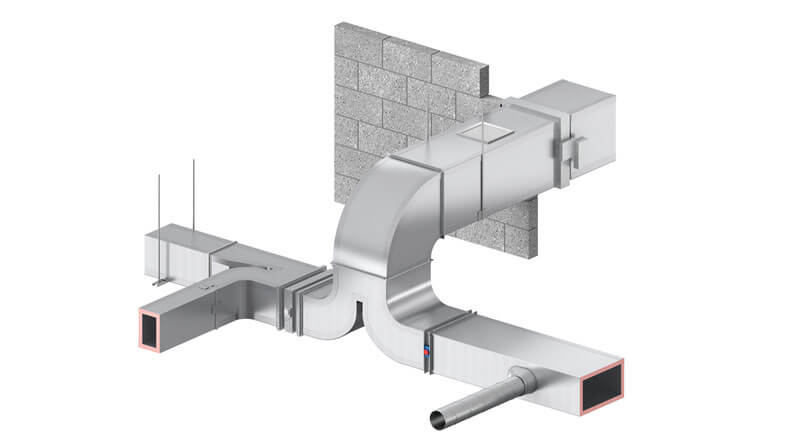

Pre-insulated ductwork has become increasingly popular in modern HVAC installations. These systems are manufactured with insulation integrated into the duct panels or pipes, providing a ready-to-install solution that minimizes onsite labor and material handling. Investing in pre insulated ductwork offers numerous benefits over traditional duct systems, particularly in terms of energy efficiency, installation speed, and long-term maintenance.

Installation Process and Time

One of the main differences between pre-insulated and traditional duct systems is the installation process. Traditional ductwork typically involves fabricating metal or fiberboard ducts onsite, followed by wrapping or applying insulation separately. This multi-step process can be labor-intensive and requires skilled workers to ensure proper insulation coverage and airtight sealing.

Pre-insulated ductwork, on the other hand, is delivered to the site with insulation already integrated. This eliminates the need for additional wrapping and reduces installation time significantly. Contractors can install these ducts quickly with fewer workers, making pre-insulated systems an attractive option for large-scale projects or time-sensitive construction schedules. The simplified installation process also reduces the potential for human error and ensures consistent insulation quality.

Energy Efficiency and Thermal Performance

Energy efficiency is a critical consideration in modern HVAC design. Traditional duct systems can experience heat loss or gain if insulation is applied unevenly or if gaps exist at seams and joints. Inconsistent insulation coverage can reduce the overall performance of the HVAC system, resulting in higher energy consumption and increased utility costs.

Pre-insulated ductwork provides uniform insulation throughout the system, minimizing heat transfer and maintaining the desired air temperature as it travels through the ducts. This consistent thermal performance ensures optimal HVAC efficiency and can significantly lower energy bills over time. Additionally, factory-applied insulation is less likely to degrade or shift over time compared to onsite-applied insulation, maintaining long-term performance.

Air Leakage and System Airtightness

Air leakage is another important factor when comparing traditional and pre-insulated duct systems. Traditional ducts often rely on manual sealing with tape or mastic, which can be inconsistent and prone to gaps. Air leakage not only reduces system efficiency but also allows dust, pollutants, and moisture to enter the ductwork, negatively impacting indoor air quality.

Pre-insulated ductwork is designed with precision-engineered joints and seals, providing superior airtightness. Factory-fabricated ducts ensure a tight fit and reduce the likelihood of leakage, maintaining airflow efficiency and protecting indoor air quality. For environments where hygiene and controlled air conditions are critical, such as hospitals or laboratories, the airtightness of pre-insulated ducts is particularly advantageous.

Durability and Maintenance

Traditional duct systems may require periodic maintenance to repair or replace insulation that has been damaged or improperly installed. Over time, insulation can sag, separate, or deteriorate, reducing thermal performance and potentially leading to moisture accumulation and mold growth.

Pre-insulated ductwork offers enhanced durability due to its integrated design. The insulation is securely bonded to the duct surface, reducing the risk of detachment or degradation over time. Maintenance requirements are minimal, as the ducts maintain consistent performance without the need for frequent repairs or insulation replacement.

Cost Considerations

While the initial cost of pre-insulated ductwork may be higher than traditional duct systems, the long-term benefits often outweigh the upfront investment. Reduced labor costs, faster installation, and improved energy efficiency contribute to overall savings. Traditional duct systems may appear less expensive initially, but additional costs can arise from extended installation times, increased labor requirements, insulation materials, and energy losses due to inefficiency.

Evaluating total lifecycle costs, including installation, operation, and maintenance, typically favors pre-insulated duct systems for large-scale or energy-conscious projects.

Space Utilization and Flexibility

Pre-insulated ducts are often more compact than traditional ducts that require separate insulation, allowing for better use of ceiling or wall space. They are available in a variety of shapes and sizes, offering flexibility for complex building layouts. Traditional ducts may require additional space for insulation thickness, potentially limiting design options in confined areas.

Environmental Impact

Energy efficiency and reduced material waste also make pre-insulated ductwork a more environmentally friendly choice. Lower energy consumption reduces greenhouse gas emissions, and factory-applied insulation ensures minimal waste during manufacturing and installation. Traditional duct systems may generate more waste due to offcuts, onsite insulation errors, or inefficiencies in energy use.

Conclusion

When comparing pre-insulated ductwork with traditional duct systems, several key differences emerge in terms of installation, energy efficiency, durability, and overall cost. Pre-insulated ducts provide faster installation, uniform insulation, airtight performance, and lower long-term maintenance, making them a highly effective solution for modern HVAC applications.

While traditional ducts may still be suitable for certain projects, the advantages of pre-insulated ductwork — including energy savings, space efficiency, and improved indoor air quality — often make them the preferred choice for contractors and building owners seeking efficient and reliable HVAC performance.