Selecting the right industrial marking machine is a critical decision for any manufacturing facility. The right machine not only ensures accurate and durable markings but also enhances production efficiency and compliance with industry regulations. With a variety of technologies and features available, it is important for factory managers to understand their options and match them with specific operational needs.

Collaborating with a reputable industrial marking machine manufacturer can simplify the selection process. Experienced manufacturers provide guidance on the best machine types, materials compatibility, and production capacities, ensuring the equipment aligns with your factory’s workflow. Their expertise also helps prevent costly mistakes and ensures smooth integration into your production line.

Understand Your Production Needs

Before selecting a machine, it is essential to assess your factory’s production requirements. Consider the volume of products, speed of the production line, and the types of materials you work with. High-volume operations may benefit from continuous inkjet or laser marking machines, which can keep up with rapid production speeds. Meanwhile, small to medium production lines may require small character inkjet printers or thermal transfer systems for precise and consistent marking.

Identifying the type of marking needed is also important. Do you require serial numbers, batch codes, barcodes, logos, or expiration dates? Each application has different requirements for accuracy, durability, and readability, which should guide your choice of technology.

Types of Industrial Marking Machines

Understanding the main types of industrial marking machines will help you make an informed decision:

1. Inkjet Printers:

Inkjet printers, including continuous inkjet (CIJ) systems, are versatile and capable of marking moving products quickly. They are ideal for high-speed lines and can handle a variety of surfaces, including metals, plastics, and glass.

2. Laser Marking Machines:

Laser systems etch permanent, highly durable marks. They are low-maintenance and produce precise, high-quality markings suitable for metals and plastics. Laser marking is especially valuable when tamper-proof or long-lasting identification is required.

3. Dot Peen Marking Machines:

Dot peen machines create indentations on surfaces using a stylus. These marks are permanent and suitable for industrial parts exposed to harsh conditions. They are commonly used in automotive, aerospace, and heavy machinery applications.

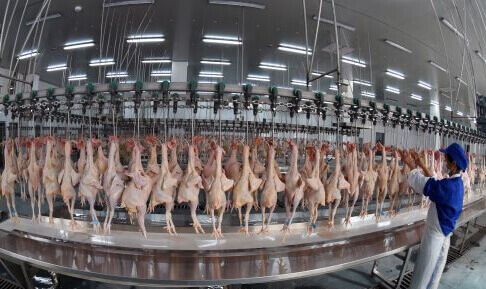

4. Thermal Transfer Printers:

These printers transfer ink from a ribbon onto packaging or flexible materials. They produce high-resolution text, barcodes, and images, making them ideal for labeling applications in food, pharmaceutical, and consumer goods industries.

Key Features to Consider

When evaluating industrial marking machines, several features should be considered:

- Material Compatibility: Ensure the machine can handle the specific materials used in your production line.

- Production Speed: Match the machine’s speed with your line’s throughput to avoid bottlenecks.

- Marking Quality: Consider the resolution, size, and clarity of the marks required.

- Durability: Evaluate if the marks need to withstand heat, chemicals, or abrasion.

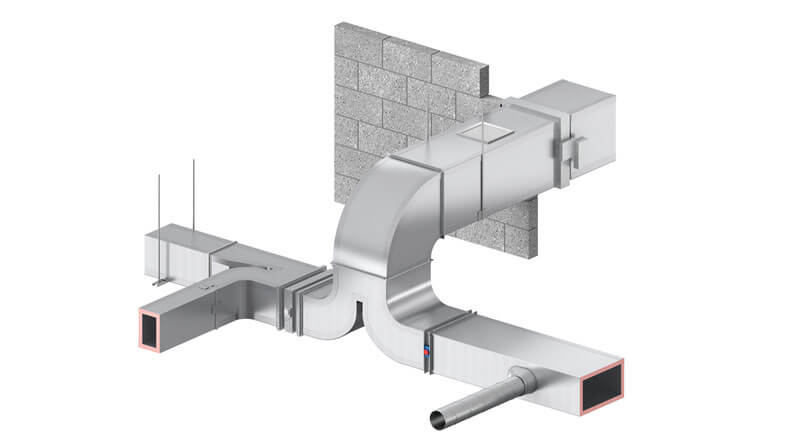

- Automation and Integration: Machines that integrate with conveyors or robotic systems enhance efficiency and reduce manual intervention.

- Maintenance Requirements: Low-maintenance machines with readily available consumables reduce downtime and operational costs.

Benefits of Choosing the Right Machine

Selecting the right industrial marking machine offers multiple advantages. Accurate and durable markings improve traceability, reduce errors, and ensure compliance with regulatory standards. Automated systems increase production efficiency, allowing employees to focus on other tasks while minimizing labor costs. Additionally, machines that can handle multiple materials and product sizes provide flexibility for future production changes or expansions.

Partnering with an Industrial Marking Machine Manufacturer

A reliable industrial marking machine manufacturer can guide you through the selection process and provide solutions tailored to your factory’s needs. Manufacturers often offer training, technical support, and maintenance services, ensuring that your investment delivers long-term value. Collaborating with an experienced provider reduces the learning curve and allows for a smoother implementation of marking systems into existing production workflows.

Conclusion

Choosing the right industrial marking machine is essential for any factory seeking efficiency, accuracy, and compliance. By understanding production needs, evaluating marking technologies, and considering key features, manufacturers can make informed decisions that enhance operational performance. Partnering with a trusted industrial marking machine manufacturer ensures that you select the optimal machine for your specific requirements, improving productivity, maintaining high-quality standards, and supporting long-term growth in your manufacturing operations.