Selecting the right punch press machine manufacturer is a critical decision for any industrial operation. Punch press machines are central to metalworking, fabrication, and manufacturing processes, performing tasks such as cutting, shaping, and forming metal sheets with precision. Choosing a reliable manufacturer ensures that the equipment delivers consistent performance, meets production requirements, and minimizes downtime. Understanding the key factors to consider can help businesses make informed decisions and secure long-term value from their investment.

Experience and Industry Reputation

One of the first aspects to evaluate when choosing a punch press machine manufacturer is their experience and reputation in the industry. Established manufacturers with a long track record are more likely to produce high-quality, durable machines. Their experience allows them to address common operational challenges and provide solutions tailored to specific industrial needs. Checking references, reviewing customer testimonials, and researching case studies can help identify manufacturers with a proven history of reliability, precision, and consistent performance. A strong industry reputation is often an indicator of both quality and customer service standards.

Quality, Technology, and Innovation

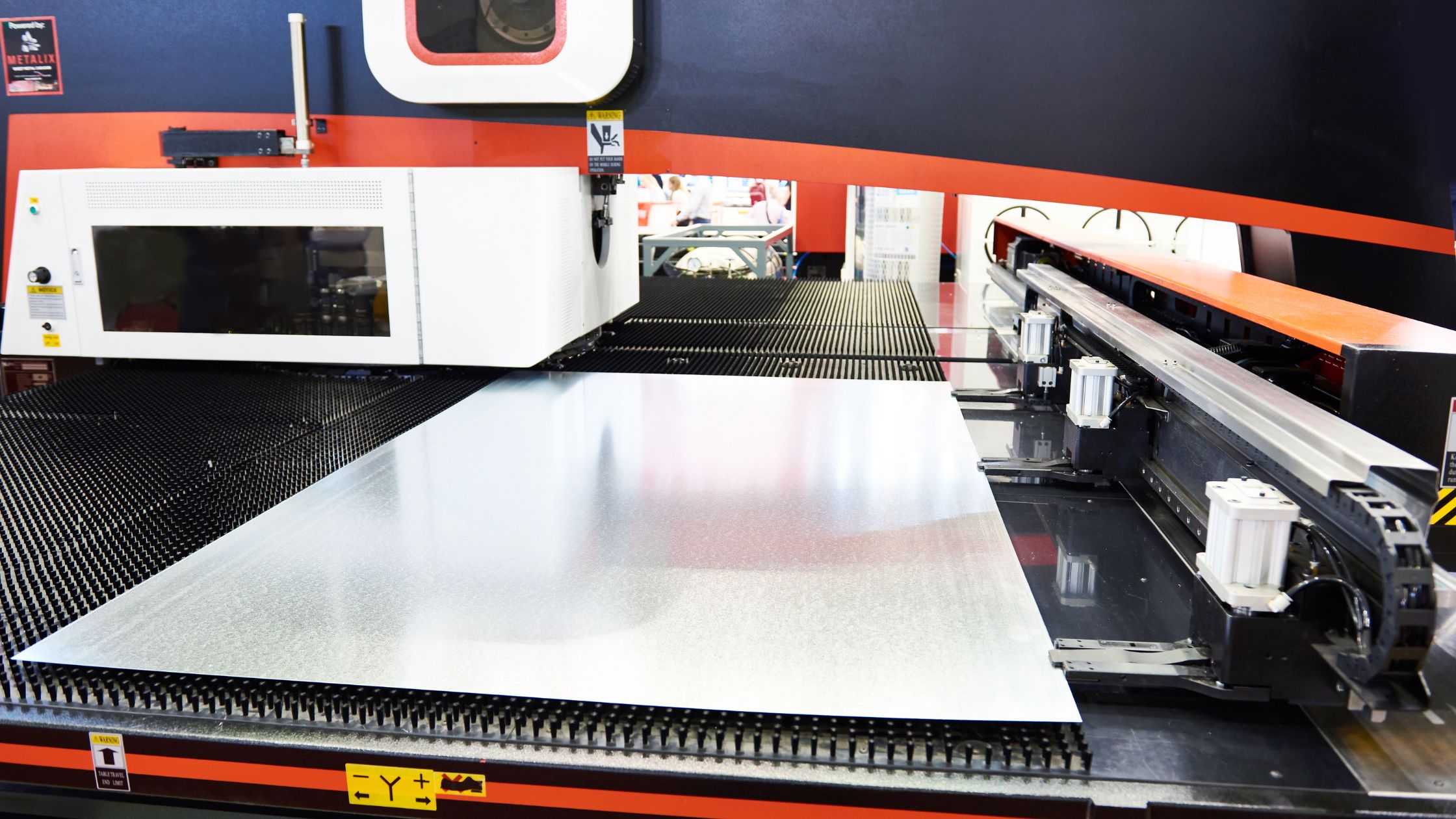

Modern industrial operations demand machines that combine durability with advanced technology. Leading Punch Press Machine Manufacturers invest heavily in research and development to incorporate automation, energy-efficient systems, and advanced control technologies into their machines. High-quality materials, precision-engineered components, and robust construction are essential for long-term performance, while technological innovations such as CNC integration and programmable automation enhance productivity and accuracy. Evaluating the manufacturer’s technological capabilities ensures that the equipment will meet both current production needs and future requirements.

Customization and Flexibility

Different industries and operations have unique requirements for punch press machines, making customization an important consideration. A reliable manufacturer should offer flexible solutions that can be adapted to specific production needs, including modifications in stroke length, die configurations, material handling systems, and automation levels. Customization not only improves efficiency but also ensures compatibility with existing workflows. Engaging manufacturers that can provide tailored solutions demonstrates their commitment to meeting the unique demands of your business.

After-Sales Support and Service

Even the most well-built punch press machines require maintenance, occasional repairs, and technical support. Manufacturers that provide comprehensive after-sales support are valuable partners in ensuring the longevity and consistent performance of the equipment. Key aspects to evaluate include the availability of spare parts, response times for service requests, and the expertise of the technical support team. On-site assistance, training programs for operators, and preventive maintenance services are additional indicators of a manufacturer’s dedication to customer satisfaction. Reliable support reduces downtime, enhances productivity, and protects your investment over time.

Safety and Compliance

Safety is a critical factor when operating punch press machines, which involve high-speed cutting and shaping processes. Manufacturers that prioritize safety in both design and operation demonstrate a responsible approach to workplace protection. Modern machines are equipped with emergency stop buttons, protective guards, light curtains, and user-friendly interfaces to minimize the risk of accidents. Compliance with international safety standards and certifications is also essential, ensuring that machines meet regulatory requirements and provide a safe working environment for operators.

Pricing and Value Considerations

While cost is an important factor, it should be evaluated in the context of overall value. A lower-priced machine may seem appealing initially but could result in higher operational costs due to maintenance issues or shorter lifespan. Conversely, investing in a high-quality, technologically advanced machine may offer greater efficiency, durability, and productivity over time. Consider factors such as energy efficiency, automation capabilities, precision, and warranty services when assessing the true value of a punch press machine. A well-balanced approach ensures that your investment provides long-term benefits rather than short-term savings.

Reputation for Reliability

Reliability is a key indicator of a manufacturer’s quality. Machines that consistently perform under heavy workloads with minimal downtime are essential for meeting industrial production targets. Evaluating reliability involves reviewing technical specifications, customer feedback, and real-world performance metrics. A manufacturer that consistently delivers dependable machines and maintains strong relationships with clients demonstrates trustworthiness and a commitment to excellence.

Conclusion

Choosing a reliable punch press machine manufacturer requires careful consideration of experience, technological innovation, customization capabilities, after-sales support, safety, and overall value. By focusing on these factors, businesses can select a manufacturer that provides durable, efficient, and precise machines tailored to their industrial needs. Partnering with reputable Punch Press Machine Manufacturers ensures access to advanced technology, high-quality construction, and ongoing support, enabling smooth operations, enhanced productivity, and long-term success in a competitive manufacturing environment.