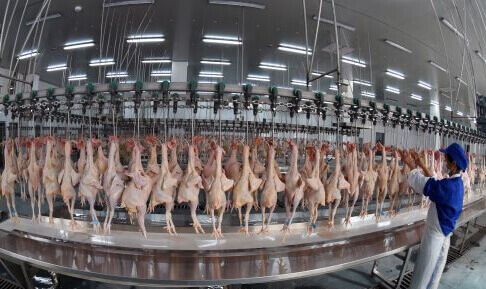

Investing in slaughtering equipment is a significant decision for any meat processing facility. The machinery used in slaughterhouses directly impacts productivity, product quality, safety, and operational efficiency. However, the initial purchase price is only one aspect of the total cost. To make a smart investment, facility managers must consider several factors, including installation, maintenance, energy consumption, and long-term operational benefits. Understanding these cost considerations helps businesses balance quality, efficiency, and financial planning.

Initial Purchase and Equipment Quality

The first cost consideration is the initial purchase price of the slaughtering equipment. High-quality machinery often comes with a higher upfront cost, but it can offer better durability, precision, and safety features. Investing in reliable equipment reduces the risk of frequent breakdowns, lower productivity, and costly repairs. High-end machines are typically made of corrosion-resistant materials, feature advanced automation, and provide better hygiene standards. For facilities looking to achieve long-term efficiency and reliability, investing in premium slaughtering equipment ensures a balance between initial expenditure and operational value.

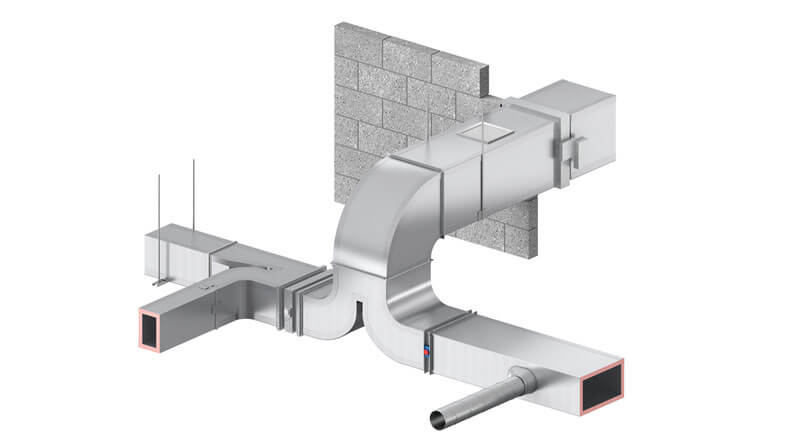

Installation and Setup Costs

Beyond the purchase price, installation and setup are critical cost factors. Slaughtering equipment often requires professional installation to ensure proper alignment, safe operation, and compliance with safety regulations. This may include electrical wiring, plumbing for water systems, integration with conveyors, and calibration of automated controls. While these costs add to the initial investment, proper installation prevents operational inefficiencies and reduces the likelihood of early mechanical issues that could result in higher repair costs.

Operational and Energy Costs

Operating slaughtering equipment involves ongoing expenses, including electricity, water, lubricants, and other consumables. Modern energy-efficient machinery can reduce power consumption significantly, lowering utility bills over time. Machines with automated controls and optimized workflow designs consume less energy while maintaining high productivity levels. Facilities should consider not only the power requirements but also the efficiency of heating, refrigeration, and water systems associated with the equipment. Investing in energy-efficient machinery can provide substantial long-term savings and reduce the facility’s environmental impact.

Maintenance and Repair Expenses

Maintenance is another critical cost consideration when investing in slaughtering equipment. Regular maintenance, including cleaning, lubrication, inspection, and timely replacement of worn parts, ensures that machinery operates at peak performance. Neglecting maintenance can lead to breakdowns, contamination risks, and increased repair expenses. When evaluating equipment, it is essential to consider ease of maintenance, availability of spare parts, and the cost of specialized labor. Machines that are durable and simple to maintain tend to offer better value over their operational lifespan, despite a higher initial purchase price.

Training and Workforce Costs

The effective use of slaughtering equipment depends on properly trained personnel. Investment in employee training is necessary to ensure safe and efficient operation, adherence to hygiene standards, and correct handling of machinery. Training costs include both initial instruction and periodic refreshers, especially for automated or technologically advanced equipment. Facilities should factor in the potential productivity gains from having a well-trained workforce, which can offset the costs of training over time by reducing errors, downtime, and waste.

Depreciation and Long-Term Value

Depreciation is a financial consideration that affects the overall cost of slaughtering equipment. High-quality machinery retains value longer and often has a lower total cost of ownership compared to lower-grade alternatives. Calculating depreciation helps facilities plan for future upgrades or replacements and assess the return on investment. Investing in reliable, durable equipment may have higher upfront costs but provides better long-term value by reducing frequent replacements and minimizing operational interruptions.

Compliance and Regulatory Costs

Slaughtering equipment must comply with hygiene, safety, and environmental regulations. Non-compliance can result in fines, penalties, or operational shutdowns, increasing the total cost of ownership. Investing in certified equipment designed to meet regulatory standards helps avoid these risks. Compliance-focused machinery often includes features like automated cleaning systems, safety guards, and advanced monitoring tools, which contribute to both safety and productivity.

Conclusion

Cost considerations when investing in slaughtering equipment go far beyond the initial purchase price. Factors such as installation, energy consumption, maintenance, training, depreciation, and regulatory compliance all contribute to the total cost of ownership. By carefully evaluating these aspects, facilities can select machinery that balances upfront expenditure with long-term operational efficiency and reliability. Investing in high-quality slaughtering equipment ensures safe, hygienic, and productive meat processing operations while providing long-term financial and operational benefits.