Operating a Swiss-type automatic lathe involves handling high-speed cutting tools, rotating workpieces, and complex machinery. While these machines are designed for precision and efficiency, ensuring operator safety and protecting equipment require strict adherence to safety protocols. Understanding potential hazards and implementing preventive measures is essential for maintaining a secure working environment.

Importance of Training and Operator Awareness

One of the most critical aspects of safety is ensuring that operators are thoroughly trained. Proper training should cover machine setup, programming, tool handling, and emergency procedures. Operators must be aware of the risks associated with moving parts, high-speed rotations, and automatic feed mechanisms. Regular training updates help ensure that all personnel stay current with best practices and safety standards, reducing the likelihood of accidents in the workshop.

Personal Protective Equipment (PPE) Requirements

Using appropriate personal protective equipment (PPE) is essential when operating a Swiss-type lathe. Safety glasses or face shields protect the eyes from flying chips and coolant splashes, while protective gloves prevent injuries during tool changes and material handling. Additionally, wearing suitable clothing that is free of loose items helps avoid entanglement with rotating components. Ensuring PPE compliance throughout the facility is a fundamental aspect of machine safety.

Machine-Specific Safety Features

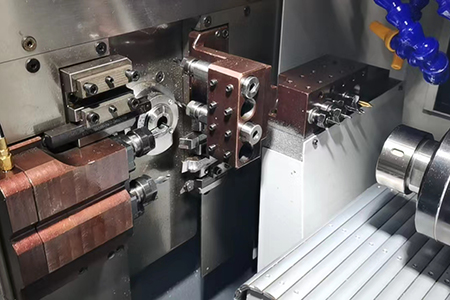

Modern Swiss-type lathes incorporate several safety features designed to reduce risk. Emergency stop buttons, interlocked guards, and protective shields prevent accidental contact with moving parts. Regular inspection and maintenance of these safety systems are critical to ensure they function correctly. Integrating safety features into daily operational routines helps protect both operators and the machine from damage.

A swiss type automatic lathe machine, in particular, requires attention to its unique sliding headstock and guide bushing design. Proper guarding around these components, combined with adherence to manufacturer guidelines, prevents potential accidents caused by entanglement or improper feeding of bar stock. Understanding the specific design of the machine is crucial for maintaining a safe work environment.

Safe Tooling and Workpiece Handling

Incorrect tooling or mishandling of materials can lead to severe accidents. Operators should always ensure tools are securely mounted, properly aligned, and in good condition before starting any operation. Workpieces should be adequately supported and checked for straightness to avoid slippage or deflection during machining. Implementing these precautions minimizes the risk of flying debris and tool breakage, which could harm operators or damage the machine.

Proper Maintenance and Inspection

Regular maintenance not only extends the life of the machine but also enhances safety. Inspecting the lathe for wear, loose components, or lubrication issues helps prevent malfunctions that could lead to accidents. Maintaining coolant systems, tool holders, and feed mechanisms ensures smooth operation and reduces the risk of unexpected machine behavior. Keeping a detailed maintenance log is a practical approach to ensuring that safety checks are not overlooked.

Awareness of Ergonomic Risks

Operating a Swiss-type lathe for extended periods can pose ergonomic challenges. Proper workstation setup, including the positioning of controls and worktables, helps reduce strain on the operator. Adjustable seating and support for repetitive tasks minimize fatigue, which can otherwise lead to lapses in attention and safety incidents. Addressing ergonomic risks is an often-overlooked aspect of machine safety but is crucial for long-term operator health.

Emergency Procedures and Response

A well-prepared workshop includes clear emergency procedures. Operators should know how to quickly stop the machine, address coolant spills, or respond to tool breakage incidents. Conducting regular safety drills and providing easy access to fire extinguishers, first-aid kits, and emergency exits ensures that personnel can act swiftly and efficiently during unexpected situations.

Safety Culture and Continuous Improvement

Fostering a culture of safety within the manufacturing environment reinforces the importance of safe machine operation. Encouraging operators to report hazards, share best practices, and participate in safety audits contributes to continuous improvement. A proactive approach to safety not only protects workers but also enhances productivity by minimizing accidents and unplanned downtime.

Conclusion

Safety considerations are paramount when operating a Swiss-type automatic lathe. Comprehensive training, proper PPE, and adherence to machine-specific safety features ensure that operators can work efficiently without unnecessary risk. Attention to tooling, maintenance, ergonomics, and emergency preparedness further strengthens the overall safety framework. By cultivating a strong safety culture, manufacturers can protect personnel, maintain machine reliability, and achieve consistent, high-quality production outcomes.