When it comes to mixing and heating liquids efficiently in industries like food processing, pharmaceuticals, or chemicals, the right equipment makes all the difference. One such essential piece of equipment is the dimple jacketed mixing tank. You might be wondering, “What exactly is a dimple jacketed mixing tank, and why is it so important?” Let’s break it down in simple terms and explore how this clever design can help improve your mixing process with some easy-to-understand examples.

What Is a Dimple Jacketed Mixing Tank?

A dimple jacketed mixing tank is a special type of container used for blending liquids, which also allows precise heating or cooling of its contents. Imagine a big metal container with a special “jacket” — a layer that wraps around the tank — but this jacket isn’t smooth. Instead, it has a pattern of small dimples or bumps all over its surface. These dimples create tiny pockets where heating or cooling fluids, like steam or chilled water, can flow evenly around the tank.

Why does this matter? The dimples increase the surface area that touches the heating or cooling fluid, which means temperature control happens faster and more efficiently. It’s like the difference between spreading butter on a smooth piece of bread versus one that has small ridges—more surface contact speeds things up!

How Does a Dimple Jacketed Mixing Tank Work?

Let’s picture a pot of soup on the stove. If you want to heat it evenly, you stir it while the heat comes from the bottom. But in industrial tanks, stirring isn’t always enough, and heat needs to be spread evenly all around the tank. This is where the dimple jacket comes in.

The jacket wraps around the outside of the tank with its dimpled surface. Hot or cold fluid passes through the jacket, flowing through the dimples and transferring heat to or from the tank walls. Because of the dimples, the fluid swirls and moves more turbulently, improving heat transfer and preventing hot or cold spots. Meanwhile, the mixing blades inside the tank ensure the liquid contents are continuously blended.

This design helps keep temperature consistent throughout the entire liquid volume, which is critical when working with heat-sensitive ingredients like chocolate, creams, or pharmaceuticals.

Why Choose a Dimple Jacketed Mixing Tank?

You might be asking yourself, “Why not just use a smooth jacketed tank or another heating method?” The dimple jacket offers several advantages:

- Efficient Heat Transfer: The dimpled pattern allows faster and more even heating or cooling, reducing processing time and saving energy.

- Lightweight and Strong: The dimples add structural strength to the jacket without making it heavy, meaning the tank can handle pressure and temperature changes better.

- Easy to Clean: Because the jacket is integrated and doesn’t require extra insulation, it’s simpler to maintain hygiene standards — which is especially important in food or pharmaceutical industries.

- Flexible Temperature Control: Whether you need to heat up or cool down, dimple jackets allow quick response to temperature changes, helping maintain product quality.

Real-Life Example: Making Chocolate

Imagine a chocolate maker trying to melt and mix chocolate evenly without burning it. Chocolate is very sensitive to temperature, and even slight overheating can ruin its texture and taste. A dimple jacketed mixing tank helps by circulating warm water through the dimples to gently heat the tank walls while the mixer inside keeps the chocolate moving. The result? Smooth, perfectly melted chocolate with no burnt spots.

What Should You Consider When Using a Dimple Jacketed Mixing Tank?

If you’re thinking of using a dimple jacketed mixing tank for your business or project, here are some friendly tips:

- Choose the Right Size: Make sure the tank volume fits your production needs. Too small, and you’ll waste time doing many batches; too large, and you risk uneven heating if not designed properly.

- Mixing Mechanism Matters: Different liquids need different mixing speeds and blade types. For example, thick creams require slower but stronger mixing than thin liquids.

- Maintenance Is Key: Even though these tanks are designed for easy cleaning, regular inspection and maintenance keep the dimples free of build-up and ensure heat transfer efficiency.

- Material Quality: Stainless steel is common because it’s durable and hygienic, but check the grade and finish to match your product’s safety standards.

Where Are Dimple Jacketed Mixing Tanks Commonly Used?

These tanks shine in various industries where temperature control and mixing quality are crucial:

- Food & Beverage: Dairy products, sauces, syrups, chocolate, and beverages all benefit from consistent mixing and temperature control.

- Pharmaceuticals: Precise temperature management helps maintain the integrity of medicines and creams.

- Chemical Processing: Some chemical reactions require exact temperature ranges for safety and effectiveness.

- Cosmetics: Lotions, creams, and gels need gentle mixing combined with controlled heating or cooling.

How to Maximize the Benefits of Your Dimple Jacketed Mixing Tank

Getting the most out of a dimple jacketed mixing tank isn’t just about buying the right tank—it’s also about using it smartly:

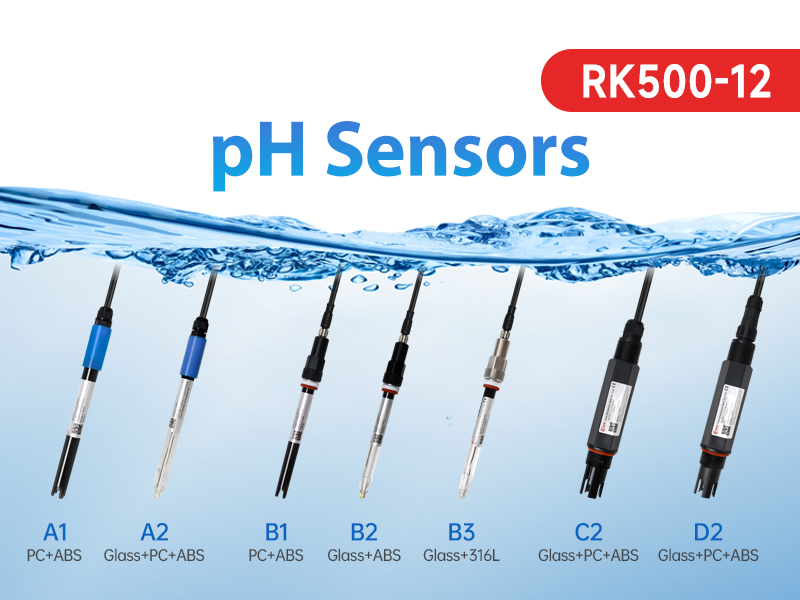

- Monitor Temperatures Closely: Use sensors to constantly check temperatures inside the tank and jacket to avoid overheating or undercooling.

- Regularly Calibrate Your Equipment: Proper calibration ensures your mixing and heating are operating as expected.

- Train Operators Well: Those handling the tanks should understand how the jacket and mixer work together for best results.

- Consider Automation: Automated controls can adjust temperature and mixing speed in real time, improving product consistency.

Wrapping It Up

So, what is a dimple jacketed mixing tank? It’s a smart, efficient container designed to mix and control the temperature of liquids with ease and precision. Thanks to its unique dimpled jacket, it speeds up heating or cooling, strengthens the tank structure, and keeps your products uniform in quality.

If you’ve ever needed to heat and mix delicate materials—like melting chocolate without burning or making creamy lotions—the dimple jacketed mixing tank could be your best friend. It’s not just a piece of equipment; it’s a smart solution that makes your process smoother, faster, and more reliable.

Remember these tips when choosing and operating one, and you’ll get consistent results with less hassle. Whether you’re a small artisan or part of a large production line, this tank can make a big difference.