In the world of modern manufacturing, automatic die cutting machines have become a game-changer. These machines are designed to enhance the precision, speed, and efficiency of the die cutting process, making them indispensable in industries like packaging, printing, and automotive. If you’re new to die cutting or looking to invest in an automatic die cutting machine, this guide will provide you with all the essential information you need to understand how they work, their benefits, and why they are a must-have in today’s competitive market.

For more insights on automatic die cutting machines, visit Masterwork Group.

What is an Automatic Die Cutting Machine?

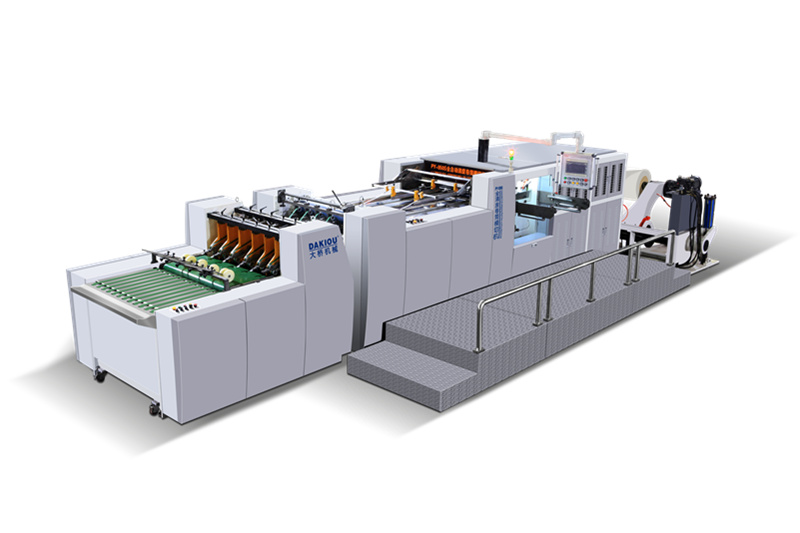

An automatic die cutting machine is a high-tech piece of equipment used to cut and shape materials with precision. Unlike traditional manual die cutting, which requires hands-on intervention, automatic die cutting machines use advanced automation to perform the cutting process efficiently and accurately. These machines are capable of cutting through a wide range of materials, such as paper, cardboard, plastic, rubber, and textiles.

The machine uses a die (a sharp metal blade or mold) to stamp or cut out predefined shapes from the material. The process is automated, meaning that the machine can continuously operate with minimal human involvement, leading to higher productivity and reduced labor costs.

Key Components of an Automatic Die Cutting Machine

Before diving into the benefits and applications, it’s important to understand the key components that make up an automatic die cutting machine:

1. Feeding System

The feeding system is responsible for transporting the material into the cutting area. It ensures that the material is fed consistently and accurately, helping to avoid any misalignment or errors during the cutting process.

2. Die Cutting Station

This is where the cutting action takes place. The die cutting station contains the die, which applies the necessary pressure to cut the material. The dies can be customized to achieve different shapes and designs.

3. Control Panel

The control panel allows operators to adjust machine settings, including the cutting speed, pressure, and material thickness. Modern machines come with digital touchscreens for easy operation and precise control.

4. Ejection System

After the material is cut, the ejection system ensures that the finished product is properly removed from the die and transported for further processing or packaging.

5. Safety Features

Automatic die cutting machines are equipped with a variety of safety features, such as emergency stop buttons, safety guards, and sensors to ensure operator safety during the cutting process.

The Benefits of Automatic Die Cutting Machines

1. Increased Efficiency and Speed

One of the primary reasons companies invest in automatic die cutting machines is the increase in efficiency and speed. These machines are designed to operate continuously without the need for frequent human intervention. The automated process significantly reduces the time required for cutting tasks, allowing businesses to handle larger volumes of work in less time.

For industries like packaging and printing, where quick turnaround times are essential, this speed boost is invaluable.

2. Enhanced Precision and Accuracy

Automatic die cutting machines are known for their high level of precision. The machines are capable of making thousands of identical cuts with minimal deviation. This level of accuracy is especially beneficial for businesses that require intricate shapes, such as custom packaging or detailed labeling.

Manual die cutting processes are prone to errors due to human limitations, but automation ensures that every cut is consistent and accurate.

3. Cost Savings

While the initial investment in an automatic die cutting machine may seem high, the long-term savings are substantial. Automation reduces the need for labor-intensive manual work, lowering labor costs and allowing companies to allocate resources more effectively. Additionally, the precision of automatic machines minimizes material waste, leading to further cost savings.

4. Versatility in Materials

Automatic die cutting machines are highly versatile and can be used to cut a wide variety of materials, from paper and cardboard to more complex materials like rubber, foam, and plastic. This versatility allows businesses to expand their product offerings and cater to different industries, from food packaging to electronics and automotive manufacturing.

5. Improved Product Consistency

Another significant advantage of automatic die cutting machines is their ability to produce consistent, high-quality results. Once the machine is set up, it will produce identical products, eliminating the variability that can occur with manual cutting. This consistency is critical for industries that require uniformity in their products, such as the medical, pharmaceutical, and automotive industries.

6. Reduced Material Waste

Automatic die cutting machines are designed to maximize material usage. They are equipped with sophisticated cutting layouts that ensure minimal waste. With precise control over the cutting process, businesses can reduce scrap material and make the most out of every roll or sheet of material.

Applications of Automatic Die Cutting Machines

Automatic die cutting machines have wide-ranging applications across many industries. Some of the most common uses include:

1. Packaging

Automatic die cutting machines are essential in the packaging industry, where they are used to cut and shape materials like cardboard and paper into boxes, cartons, and displays. The ability to create custom packaging designs is a major advantage, especially for businesses that need unique or intricate packaging for their products.

2. Printing and Labeling

In the printing industry, die cutting machines are used to create custom labels, stickers, and other printed products. The precision of automatic die cutting machines ensures that each label is cut to the exact specifications, improving the overall quality of the finished product.

3. Automotive

In the automotive industry, automatic die cutting machines are used to create various components, such as gaskets, seals, and insulation materials. The ability to handle tough materials and maintain precision is essential in this sector, where even small deviations can have serious consequences.

4. Electronics

Die cutting is also used in the electronics industry to create components like circuit boards, protective films, and insulation layers. The accuracy and consistency of automatic die cutting machines make them ideal for these high-precision applications.

5. Textiles and Apparel

Automatic die cutting machines are employed in the textile and apparel industries to cut fabrics, patterns, and even leather. The versatility of these machines allows them to handle a variety of materials used in clothing production.

Conclusion

The automatic die cutting machine has revolutionized the manufacturing industry, offering unmatched benefits in terms of efficiency, precision, cost savings, and versatility. By automating the die cutting process, businesses can improve their production timelines, reduce waste, and maintain a high level of quality across their products.

For businesses looking to streamline their production and stay competitive in today’s fast-paced market, investing in an automatic die cutting machine is a wise decision. Whether you’re in packaging, printing, automotive, or any other industry that requires die cutting, these machines are designed to meet your needs and elevate your production capabilities.

To learn more about automatic die cutting machines and explore the best options available, visit Masterwork Group.